| 牌號(hào) | 14MoV6-3 |

| 歐標(biāo)鋼號(hào) | 1.7715 |

| 對(duì)應(yīng)標(biāo)準(zhǔn) | EN 10222-2-2017

壓力用途用鋼制鍛件 第2部分 具有高溫特性的鐵素體和馬氏體鋼 Steel Forgings for Pressure Purposes. Part 2:Ferritic and Martensitic Steels with Specified Elevated Temperature Properties |

| 歸類 | 合金鋼 |

-

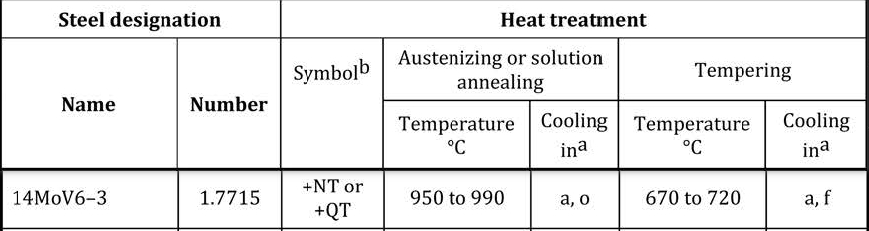

熱處理制度(僅供參考)

QT= quenched and tempered; NT= normalized and tempered. a = air; f = furnaced; o = oil; w = water or water based medium.

注:數(shù)據(jù)僅供參考!如有疑問(wèn),請(qǐng)?zhí)顚?我要糾錯(cuò)"妆跌!